Material standard:

75Nosotros8 (DE 1.5634, AISI L2).

Composición química (typical):

Carbón (C): 0.75%

Nickel (En): 1.8%

Manganeso (Minnesota): 0.30-0.50%

Silicio (Y): 0.25-0.40%

Azufre (S): ≤ 0.025%

Fósforo (PAG): ≤ 0.025%

Mechanical properties (después del tratamiento térmico):

Resistencia a la tracción: 800-1200 MPa (depending on the specific heat treatment process)

Dureza: 58-62 CDH (temple + templado)

Alargamiento: ≥ 8%

Fuerza de producción: 500-800 MPa

Proceso de tratamiento térmico:

Recocido: Soften the material and improve the machinability. The annealing temperature is about 820-860°C and cool slowly.

Temple: Heat to 780-810°C and oil cool. The hardness after quenching can reach 58-62 CDH.

Templado: Usually carried out at 150-250°C to improve toughness and reduce brittleness.

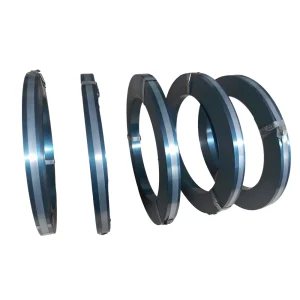

Production Specification range(milímetros): 0.10-5.0*10-1250milímetros,The length can be controlled according to customer needs.

75Ni8 steel application

75Ni8 cold-rolled heat-treated steel strip coils and plates, known for their high hardness, excelente resistencia al desgaste, y buena dureza, perform exceptionally well under quenching and tempering processes. These materials are capable of enduring high stress and wear over extended periods, making them particularly suitable for the production of cutting tools, cuchillas de sierra, and band saws. Their outstanding cutting performance and long service life have earned them widespread recognition.

In the field of stamping dies, 75Ni8 steel demonstrates excellent impact resistance and wear resistance, making it ideal for frequently used molds and high-strength processing equipment.

Además, due to its elasticity and strength, this steel grade excels in the production of springs and other elastic components, particularly those requiring high strength and long-term stress resistance. Its high precision and durability make it an ideal material for precision tool manufacturing, such as gauges, rulers, and other tools requiring high wear resistance and dimensional stability.

In the manufacture of mechanical parts, aeroespacial, and the automotive industry, 75Ni8 steel meets the demands for high strength and fatigue resistance. It is widely used in engine components, engranajes, bearings, and other critical structural parts. Además, it is suitable for high-performance shearing tools and other industrial cutting equipment, ensuring blades remain sharp for extended periods and can withstand harsh working conditions. Por lo tanto, 75Ni8 steel strip coils and plates are the preferred materials for producing high-strength, high-precision, and long-lasting components in various industrial applications.