Product Description and Application Cases

Chemical Composition Characteristics: CK45 steel is known for its high carbon content, which provides excellent hardness and strength. The precise chemical makeup includes a significant proportion of carbon (0.42%-0.50%), manganese (0.50%-0.80%), and silicon (0.17%-0.37%), contributing to its durability and resistance to wear and tear.

Physical Performance Characteristics:

- Hardness: CK45 steel offers superior hardness due to its high carbon content, making it ideal for wear-resistant applications.

- Tensile Strength: The material exhibits remarkable tensile strength, making it suitable for components subjected to high stress.

- Ductility: Despite its hardness, CK45 steel maintains a level of ductility, allowing it to be formed into various shapes and sizes without cracking.

- Heat Treatment: The steel is heat-treatable, which allows for further enhancement of its mechanical properties.

Manufacturing Process: CK45 steel coils are produced through an intricate process involving hot rolling, followed by cold drawing or precision rolling. This ensures a uniform structure and optimal physical properties. The material is typically annealed to achieve a balance of toughness and machinability.

Primary Applications:

- Automotive Industry: Used in the manufacturing of shafts, axles, and other components requiring high strength and wear resistance.

- Construction: Ideal for building frameworks and structural components due to its excellent mechanical properties.

- Machinery: Widely used in making parts like gears, spindles, and pins that need to withstand high mechanical stress.

- Tooling: Suitable for creating tools that require a high degree of hardness and durability.

Case Study: A leading automotive manufacturer incorporated CK45 steel in the production of their high-performance crankshafts. The material’s high tensile strength and superior hardness contributed to the durability and longevity of the crankshafts, reducing maintenance costs and improving vehicle performance.

Product Parameters

| Attribute | Details |

| Material | CK45 (AISI 1045) |

| Standard | EN 10083-2, ASTM A29/A29M |

| Specifications | Thickness: 1.0mm – 4.0mm <br> Width: 0.8mm – 1500mm |

| Coil Weight | 500kg – 3000kg |

| Hardness | 170 – 210 HBW |

| Dimensional Tolerances | Thickness: ±0.02mm <br> Width: ±0.5mm |

| Chemical Composition | C: 0.42%-0.50% <br> Mn: 0.50%-0.80% <br> Si: 0.17%-0.37% <br> P: ≤0.030% <br> S: ≤0.030% |

| Delivery Condition | Hot Rolled, Cold Drawn, Annealed |

| Mechanical Properties | Tensile Strength: 570 – 700 MPa <br> Yield Strength: 355 MPa min <br> Elongation: 16% min |

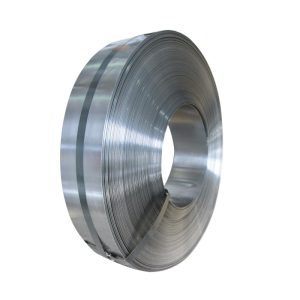

| Surface Quality | Bright, smooth, free from defects |

| Packaging | Bundled and wrapped in protective film |

| Inner Diameter | 508mm, 610mm |

| Production Lead Time | 4 – 6 weeks |

| Customization | Available on request for sizes, surface finish, and packaging |

| Range | Can be tailored to specific applications and customer requirements |

Order Your CK45 Steel Coil Today

For more information or to place an order, please contact us at sales@didiok.org or call us at +86 18924260020. Customization options are available to meet your specific needs.