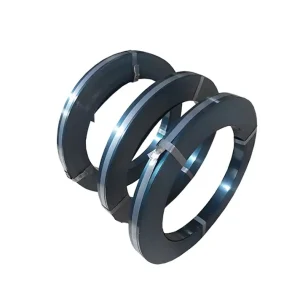

cold rolled heat treatment steel coil

Our cold-rolled heat treatment steel coil are designed for top-grade band saw blade manufacturing and provide best-in-class cutting performance. Meticulously cold rolled and precision machined, they are designed to withstand the rigors of sawing. Through the heat treatment process, the steel coil has excellent strength and durability.

Key features include increased wear resistance and uniform hardness ——all for consistent, superior blade performance in different industrial applications.

A Variety Of Colors For Hardened And Tempered Steel Strips Are Available For Your Selection

- Polished bright surface

- Blue surface

- Golden surface

Applications

band saw blade, gang saw blade, circular saw blade, etc.

Video display

Each batch of products undergoes rigorous internal quality assessment to ensure compliance with standards. We start with the selection of high-quality raw materials and pay meticulous attention to details during cold rolling, trempe, tempering and deburring to ensure that the final product reaches the highest quality.

The cold rolling stage is a critical step in shaping the material and requires close monitoring to maintain precise control of width and thickness. Advanced equipment and careful supervision by workers ensure that the products produced are uniform and precise.

The subsequent quenching and tempering process is also an integral part of improving the mechanical properties of carbon steel. Temperature, time and cooling rate are tightly controlled to achieve the desired hardness while maintaining an optimal balance between strength and ductility. Comprehensive hardness testing after treatment to verify compliance with specified hardness ranges

During the deburring stage, any remaining edge defects are meticulously eradicated. This step not only enhances the aesthetics of the heat-treated steel strip product, it also eliminates potential hazards and improves product safety.

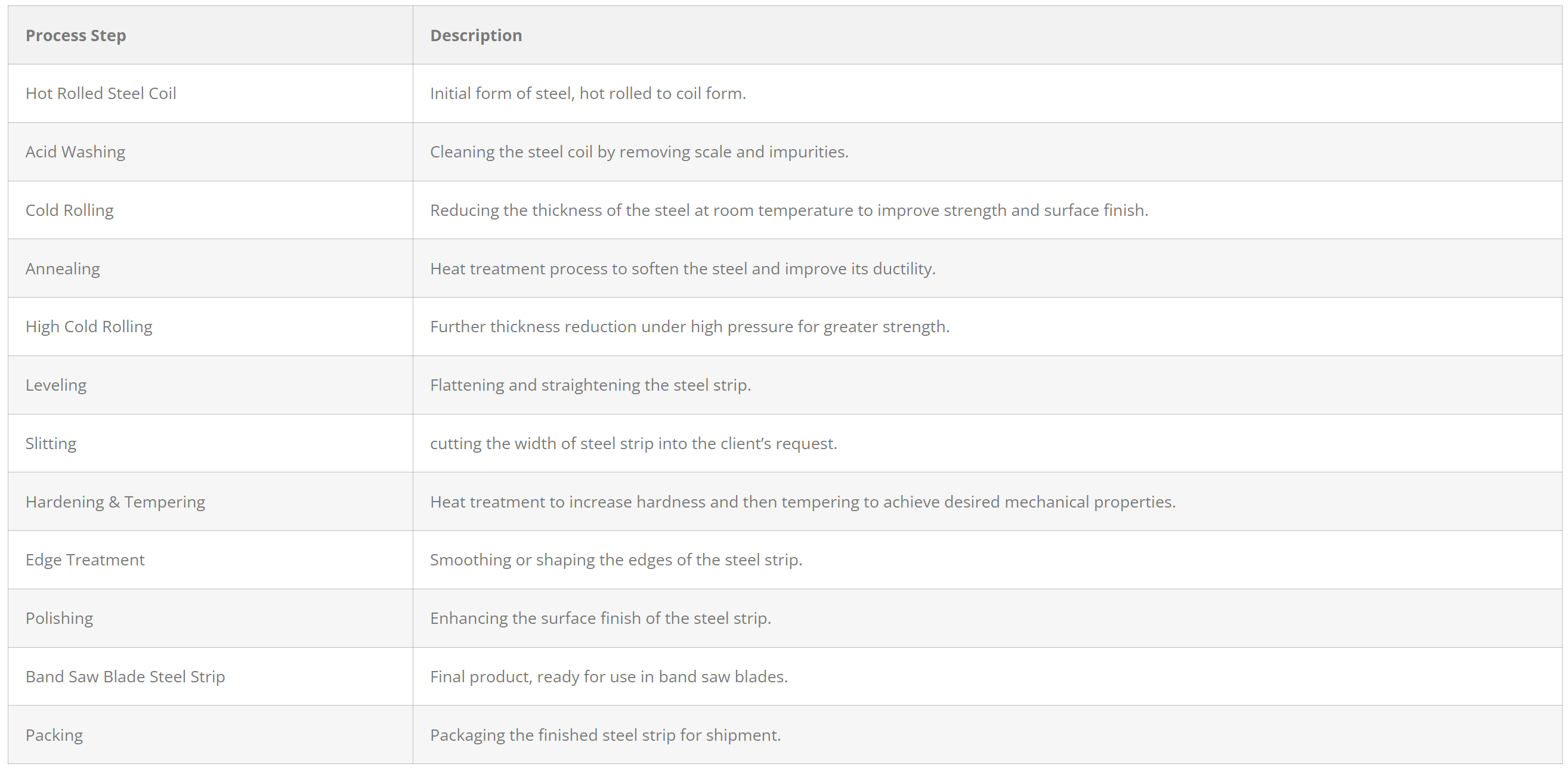

Band saw blade steel strip Production process form

| Process Step | Description |

| Hot Rolled Steel Coil | Initial form of steel, hot rolled to coil form. |

| Acid Washing | Cleaning the steel coil by removing scale and impurities. |

| Cold Rolling | Reducing the thickness of the steel at room temperature to improve strength and surface finish. |

| Annealing | Heat treatment process to soften the steel and improve its ductility. |

| High Cold Rolling | Further thickness reduction under high pressure for greater strength. |

| Leveling | Flattening and straightening the steel strip. |

| Slitting | cutting the width of steel strip into the client’s request. |

| Hardening & Tempering | Heat treatment to increase hardness and then tempering to achieve desired mechanical properties. |

| Edge Treatment | Smoothing or shaping the edges of the steel strip. |

| Polishing | Enhancing the surface finish of the steel strip. |

| Band Saw Blade Steel Strip | Final product, ready for use in band saw blades. |

| Packing | Packaging the finished steel strip for shipment. |

Product advantage

1. Excelent flatness,stable straightness

2. brilliant edges,no burrs

3. Flat surface,bright color

4, Refractory,Economical and durable

5. High temperature resistance

Product Packaging