Premium Steel Material for Manufacturing Gang Saw Blades

—— Tailored Steel Solutions for Exceptional Saw Blade Durability & Hiệu suất

By strictly controlling the cold rolling process, we ensure that the gang saw steel has a uniform structure and no internal defects, thereby improving the overall performance and service life of the blade.

Surface polishing treatment further improves the corrosion resistance and processing performance of steel.

Gang Saw Steel Applications and Hot Selling Steel Grades

Gang saw steel is a critical determinant of the precision and efficiency in stone processing, as it bears the responsibility for achieving accurate cutting on high-strength, high-hardness stones such as granite and marble. This type of steel is uniquely characterized by its exceptional hardness, Đang đeo điện trở, and outstanding impact toughness, likened to a “diamond in the rough” among steel grades, fearlessly tackling hard stone challenges.

Selected steel for gang saw blade encompass not only high-speed tool steels but also powder metallurgy high-speed steels, as well as metal composite materials enriched with hard alloy particles like tungsten carbide and titanium carbide. These steels are meticulously designed and refined through smelting processes specifically tailored to meet the stringent demands under extreme working conditions, ensuring that the saw blades maintain stable performance and a long-lasting service life during continuous operation.

As a leading manufacturer of heat-treated steel strips, we specialize in researching and providing a range of high-performance steels for gang saw blades, including models such as 68CrNiMo, C75, 75Ni8, M42, and B318. These steels serve as the unsung heroes behind precise cutting techniques, empowering the stone industry to enhance cutting efficiency and quality.

Why choose 68CrNiMo, C75, 75Ni8 as gang saw blade steel?

Adopts high quality alloy steel: 68CrNiMo, C75 and 75Ni8. Specific good elasticity, Đang đeo điện trở, high temperature resistance. The flatness is very good.

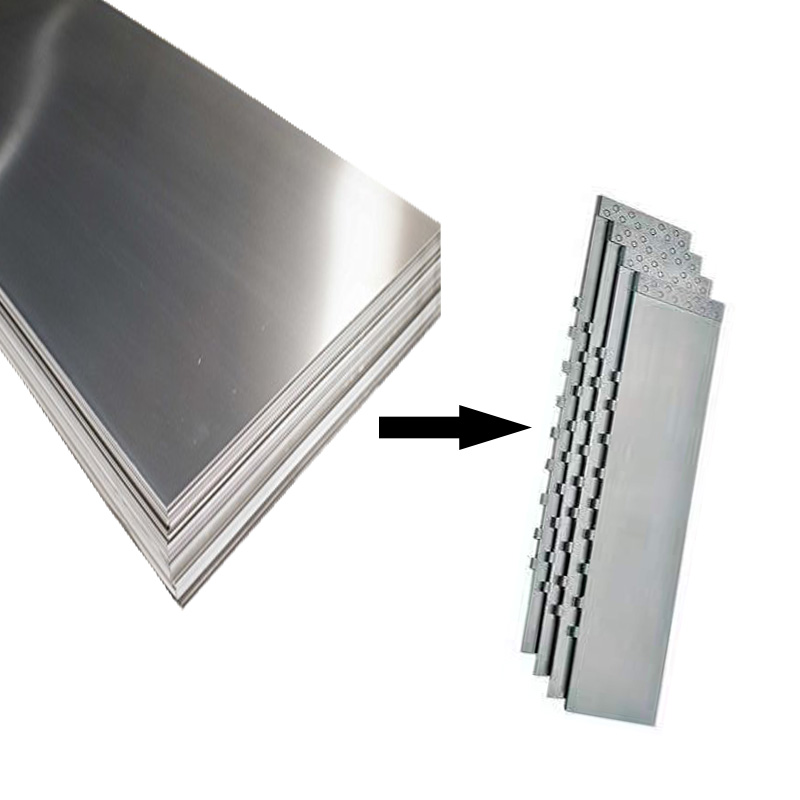

Common Specifications

We provide steel coils or plates in a variety of thicknesses, chiều rộng, and lengths to meet the manufacturing needs of Gang Saws of different specifications.

The chemical composition, mechanical properties and other parameters can be customized according to customer needs to ensure that the steel accurately matches the customer’s blade design.

Steel has good plasticity and machinability, making it easy to carry out subsequent processing steps such as cutting, hình thành, welding, and heat treatment, reducing blade manufacturing costs.

| Chiều rộng (mm) | Độ dày (mm) | Width tolerance (+/-mm) | Thickness tolerance (+/-mm) | Conversion (KG/M) |

|---|---|---|---|---|

| 180 | 2.5 | 0.50 | 0.056 | 3.53 |

| 180 | 2.0 | 0.50 | 0.05 | 2.83 |

| 180 | 1.75 | 0.50 | 0.05 | 2.51 |

| 180 | 1.6 | 0.50 | 0.05 | 2.26 |

| 180 | 1.5 | 0.50 | 0.05 | 2.11 |

gang saw steel sheet Product packaging