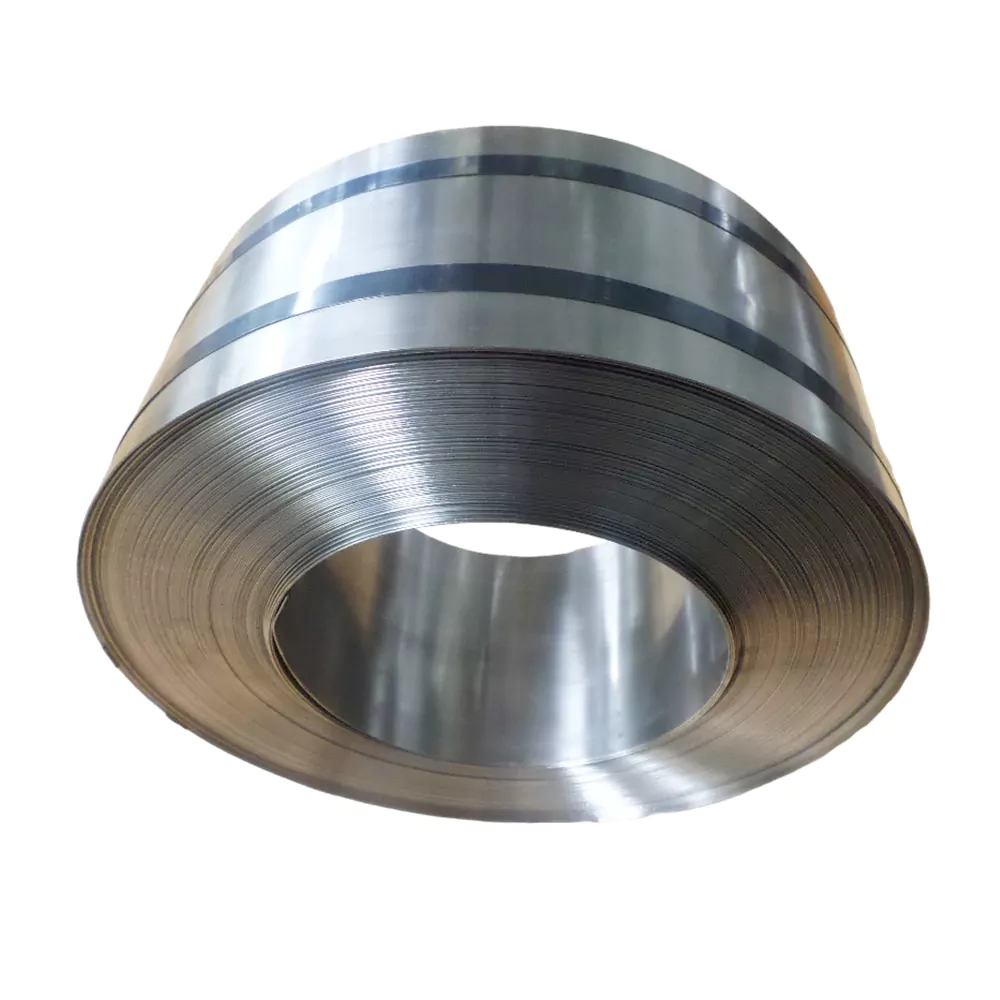

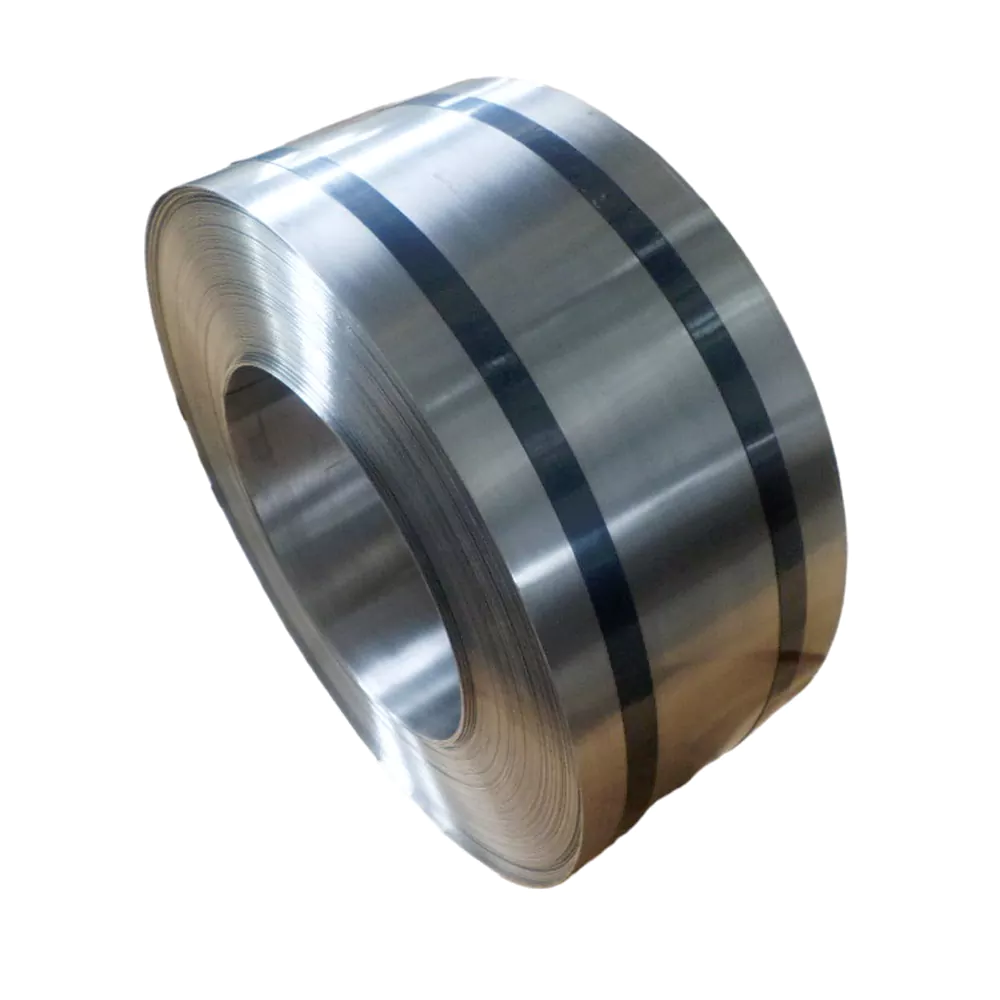

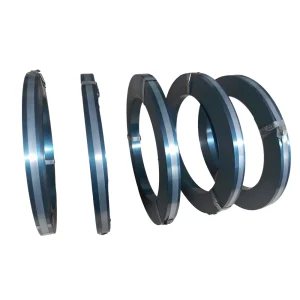

cold-rolled steel : hot rolled steel as raw material has been processed through pickling to remove the oxide scale then cold rolling. The production of cold rolled steel strips include the picking, холодная прокатка, deceasing, отжиг, выравнивание, finishing, polishing, и т. д., It not only achieves to the highest production efficiency and the most perfect automation control in the steel field by the production department, but also representing the outstanding and greatest level of steel rolling technology.

Our cold-rolled steel coils must be under further processes after annealing, including cutting head & tail, trimming, straightening, выравнивание, recoiling or slitting.etc

Delivery condition (strip,coil,лист) | Grade based on DIN Standard | High quality heat treating steel strip, coil, лист supply capacity and condition | |||

| Delivery condition (strip,coil,лист) | Grade based on DIN Standard | Твердость<20СПЧ | Hardness 29-55HRC | ||

| Delivery condition (strip,coil,лист) | Grade based on DIN Standard | отожженный | закаленный и закаленный | ||

| Delivery condition (strip,coil,лист) | Grade based on DIN Standard | толщина | Ширина | толщина | Ширина |

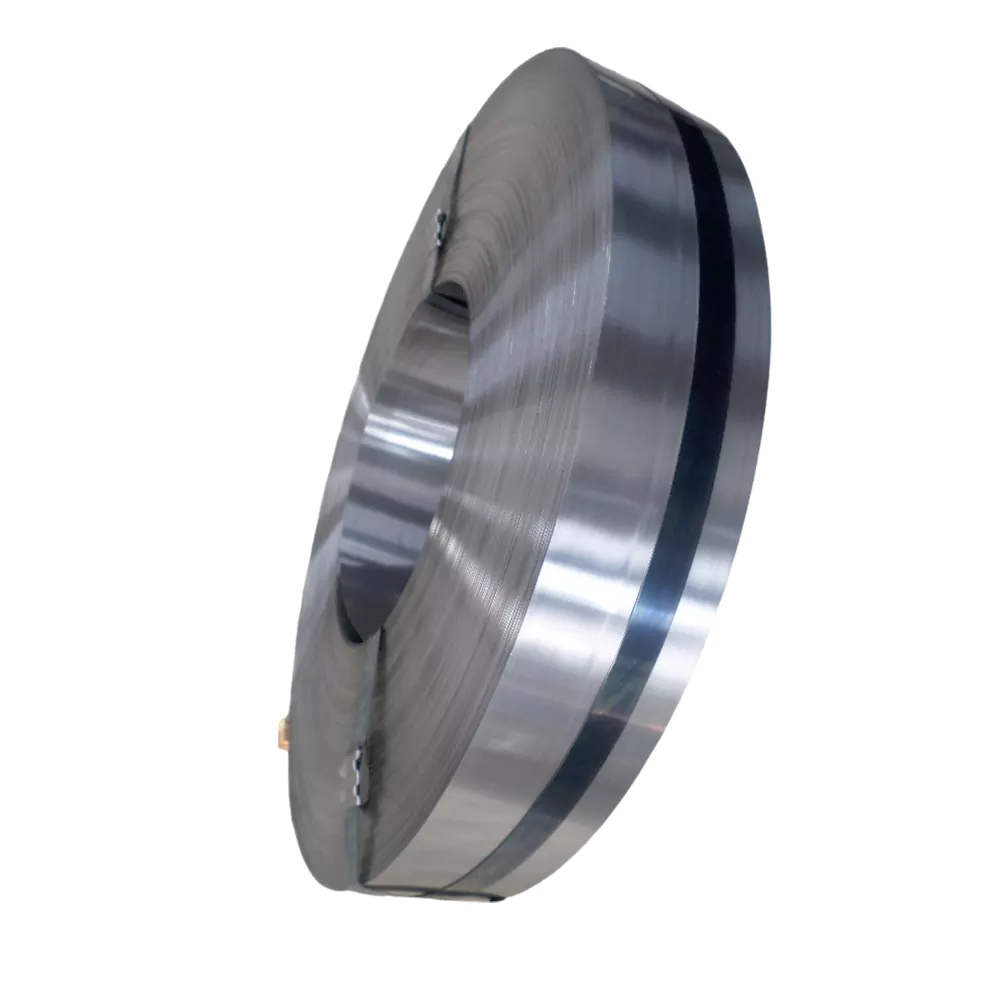

Высокая углеродная сталь | CK50,CK55, CK60,CK67, CK70,CK75,C75Cr1, СК5 SAE1050, SAE1060, SAE1065, САЭ1070 SAE1075 | 0.15-5.0мм | 8-600мм | 0.20-5.0мм | 8-600мм |

Alloy spring steel | 50КрВ4, 51КрВ4, 60Si2Mn | 0.20-5.0мм | 8-600мм | 0.20-5.0мм | 8-600мм |

Stainless spring steel | 3Cr13-6Cr13 | 0.20-5.0мм | 8-600мм | 0.20-5.0мм | 8-600мм |

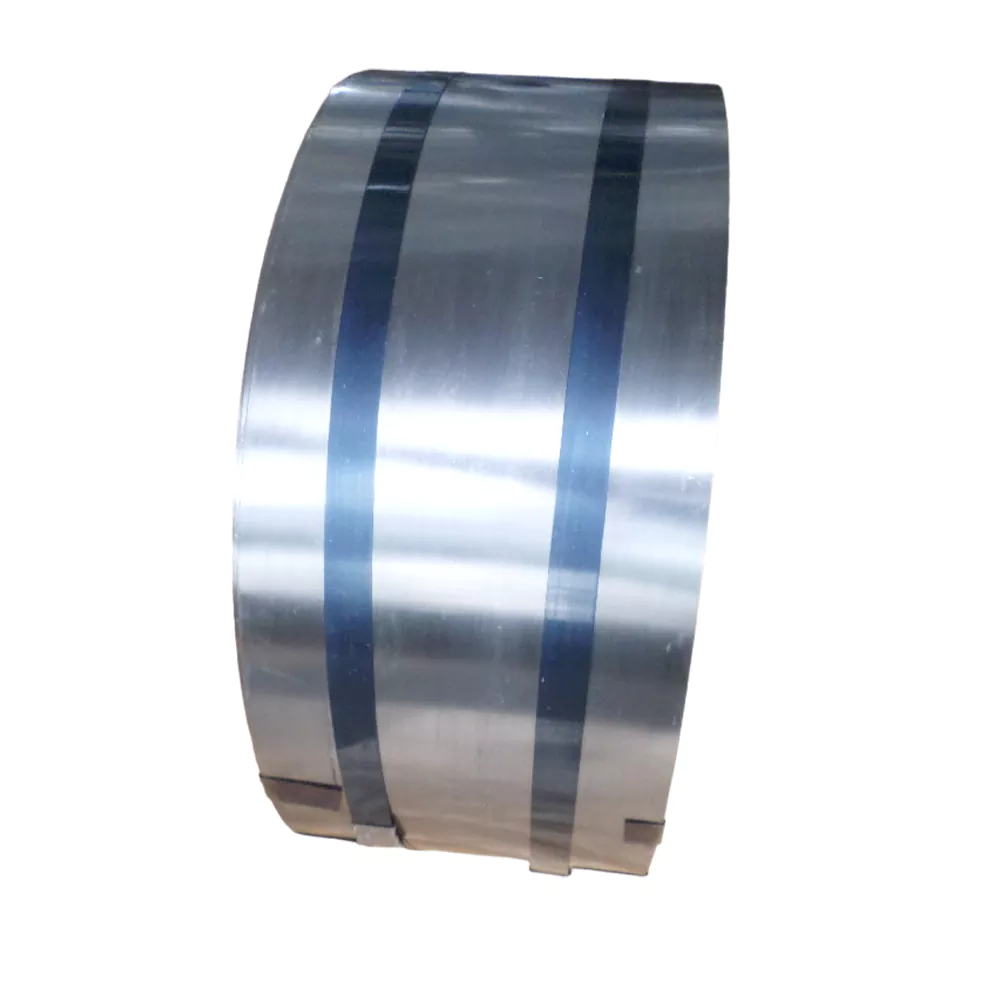

Edge process | край разреза; оба округлые; одна сторона круглая, одна боковая щель; квадрат и т. д. | ||||

Готовая поверхность | полированный (синий, желтый, белый, серо-синий, черный, яркий) или Природа и т. д. | ||||

Толерантность | thickness +/-0.03mm max; width +/-0.3mm max | ||||

Physical Property | предел прочности – 450-1850N/mm2 | ||||