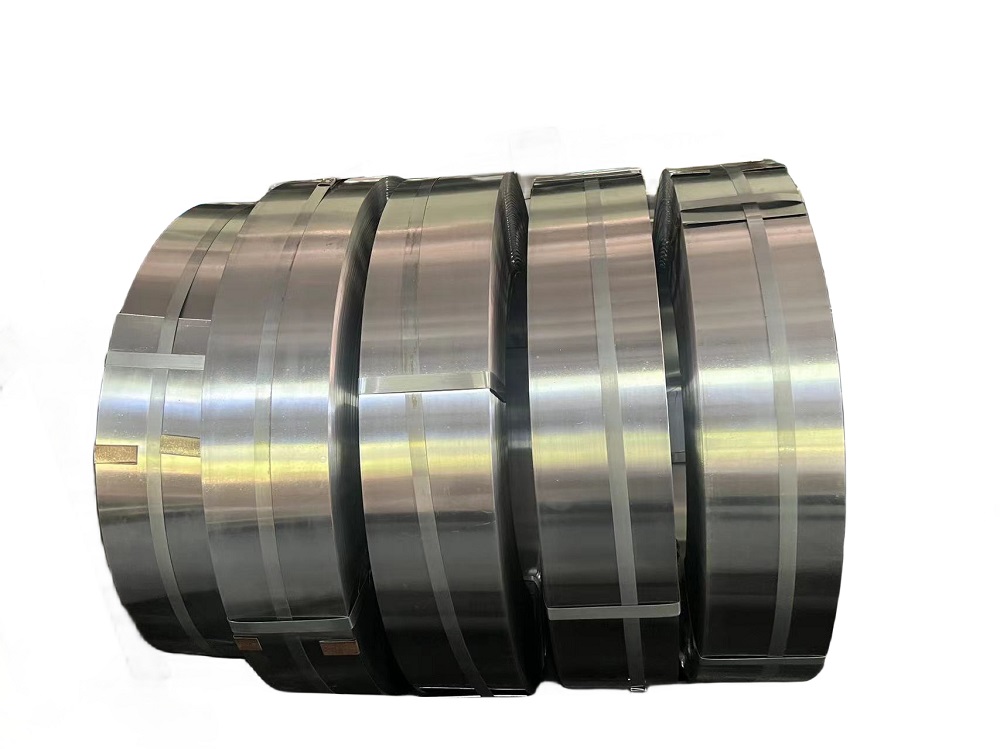

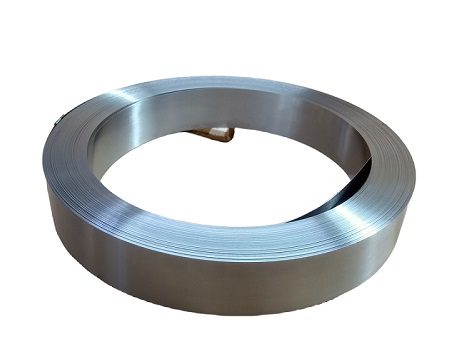

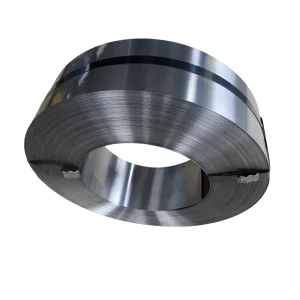

Hardened and Tempered High Carbon Alloy Steel strip for Band Saw Blades

Experience unparalleled cutting precision and durability with our premium C75 75CR1 Hardened and Tempered High Carbon Alloy Steel, specifically engineered for band saw blades. Designed to meet the rigorous demands of professional woodworking, fabrication de métaux, and various industrial applications, this material is your go-to choice for achieving exceptional performance and longevity.

C75,75cr1 high carbon alloy steel main Features & Benefits

High Carbon Alloy Composition: Our C75 75CR1 steel boasts an optimized high carbon alloy composition, ensuring enhanced hardness, wear resistance, and excellent edge retention, making it ideal for heavy-duty cutting tasks.

Hardened and Tempered Treatment: The rigorous heat treatment process involving hardening and tempering imparts superior strength, flexibility, and fatigue resistance to the steel, allowing it to withstand the stresses of continuous cutting without deformation or breakage.

Precision Cutting Performance: With its fine grain structure and consistent metallurgical properties, our C75 75CR1 steel delivers exceptional cutting accuracy, minimal tooth strippage, and reduced blade wander, resulting in clean, burr-free cuts and increased productivity.

Versatile Application Range: Suitable for cutting a wide variety of materials, including wood, plastics, non-ferrous metals, and even some ferrous metals, our C75 75CR1 steel is a versatile choice for band saw blades across various industries.

Long Service Life: Combining superior hardness, wear resistance, and fatigue strength, our steel ensures extended blade life, reducing the need for frequent replacements and minimizing downtime.

alloy carbon steel strip 75Cr1 steel for band saw blade application

If you need customized band saw blades, you can visit our saw blade factory: Cgoodsaws

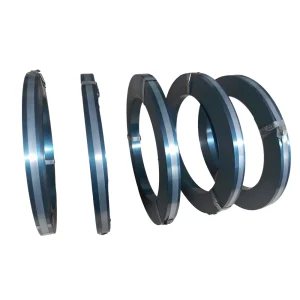

alloy carbon steel strip material grade

| Carbon Steel Strip | C45S, C50S, C55S, C60S, C62S, C67S, C70S, C75S, C80S,C95S,C100S |

| Bande d'acier allié | 75NI8,D6A,X32,B318,AISI420, 75CR1,80CRV2, 51CrV4, 60Si2Mn |

| Bimetal Steel Strip | HSS M42+D6A,HSS M42+X32,HSS M51+X32,HSS M51+D6A |

Hardened and tempered steel sheet 75Cr1 80CrV2 for making circular saw blades

Dimentions (MM) for circular saw blade steel sheet/plate | ||||

2.25*310*1240 | 2.45*260*1050 | 2.65*210*1020 | 2.55*360*1080 | 2.25*510*1000 |

1.65*500*1090 | 2.45*505*1010 | 2.84*465*1840 | 3.24*505*1505 | 2.84*455*1805 |

2.54*355*1405 | 1.8*510*1530 | 3.25*560*1120 | 2.55*410*440 | 2.45*510*1000 |

2.65*510*1000 | 3.2*505*1505 | |||

★Customized services according to customer requirements

Quality Assurance

Strictly Quality Test Before Delivery

—Jiaxiao MTC well know the most import features of the hardened and tempered steel strip material, so we will test

1)hardness test

2)flatness test

3)straightness test

4)thickness test

5)width test

6)microstructure test

during and after the production, so that we can make sure our material suitable for customer’s requirements.

High quality heat treated alloy carbon steel supplier

Uncompromising Quality, Unwavering Safety: Your Trusted Partner for Heat-Treated Steel Strip

At our facility, a dedicated team of highly skilled, seasoned, and fervent engineers relentlessly strives to comprehend and learn from our clients, perpetually driving advancements in our product offerings and operational excellence. Our steadfast commitment to core values—safety foremost, quality supreme—ensures meticulous attention to detail at every juncture.

Harnessing the profound knowledge of our engineers, cutting-edge, dependable machinery, and an efficient management framework, we are impeccably positioned to fulfill clients’ aspirations for premium-grade materials and peerless service. From raw materials to finished goods, every stage adheres stringently to both domestic and international benchmarks, meticulously overseeing chemical composition, mechanical attributes (hardness, tensile strength, elongation, yield strength, flatness tolerance, edge condition, surface finishing, and temper hue), ensuring each steel strip design surpasses even the most exacting criteria.

Geographically Advantageous, Production Robust, Global Reach

Nestled in Jiangxi Province, the Manganese Hub of Mainland China, our facility occupies approximately 2 acres, featuring a 5,000-square-meter state-of-the-art workshop and harnessing the collective expertise of 110 staff members, inclusive of proficient technical professionals. We boast a monthly production capacity of over 1,500 metric tons of superior heat-treated steel strips.

A remarkable 70% of our output is exported worldwide via maritime transport, catering to a broad spectrum of clients, including importers, traders, intermediaries, end-users, and beyond, hailing from South America, Europe, le Moyen-Orient, Far Eastern nations, the Arabian Peninsula, and Southern Africa, solidifying our position as a trusted link in the global supply chain for heat-treated steel strips.

Please contact us: Jiaxiao MTC freely customized carbon alloy steel strip coils and plates for you