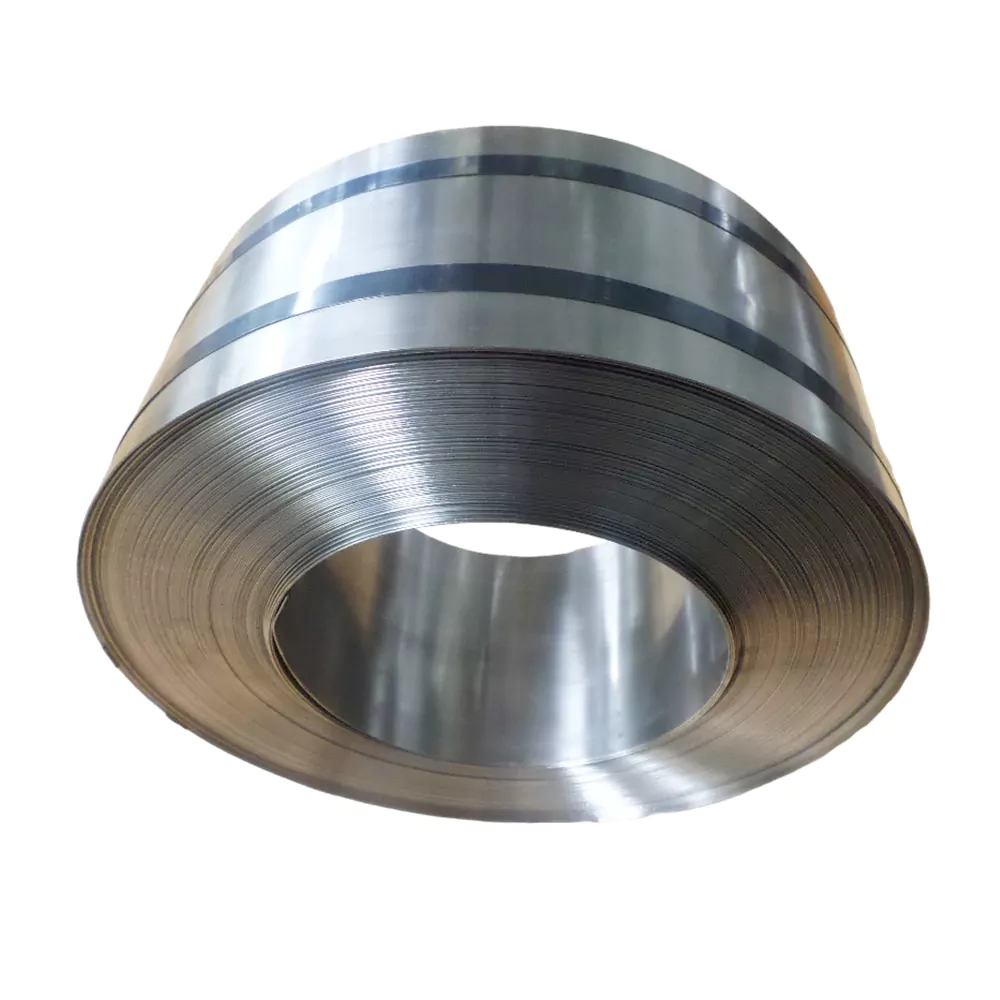

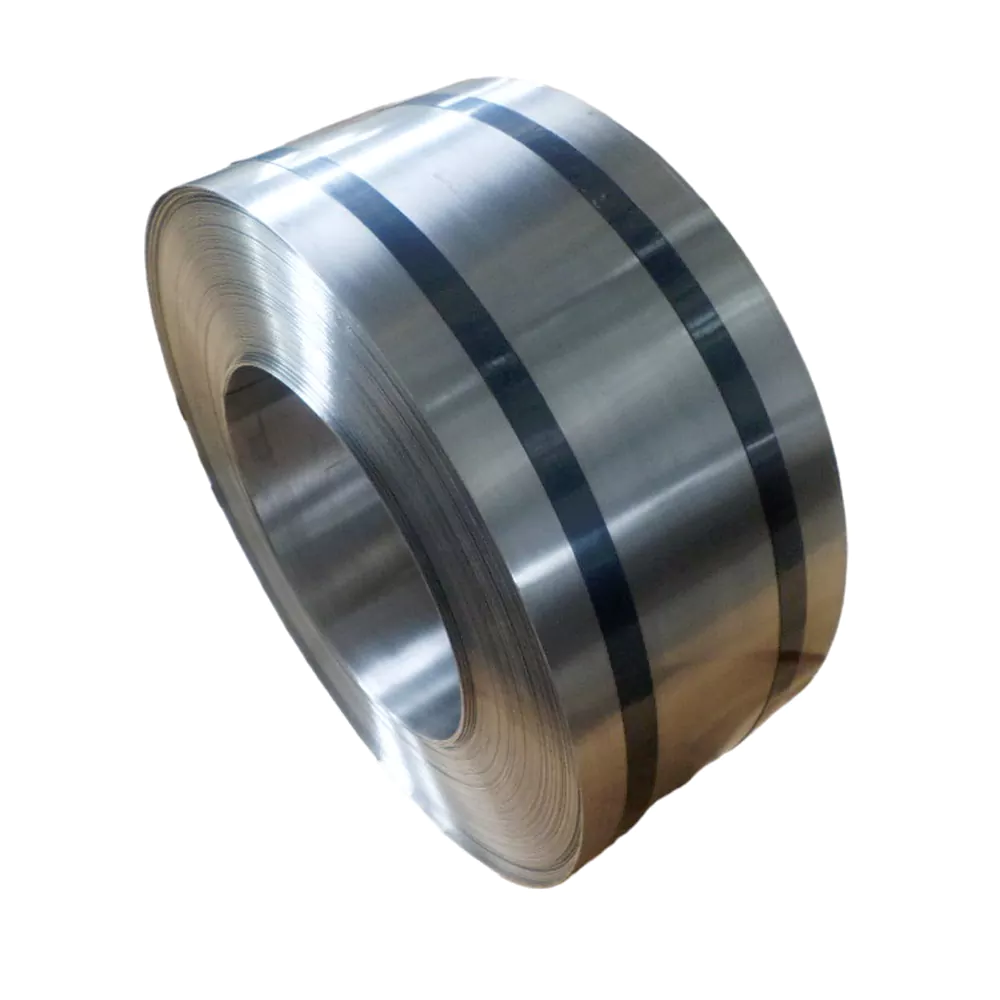

cold-rolled steel : hot rolled steel as raw material has been processed through pickling to remove the oxide scale then cold rolling. The production of cold rolled steel strips include the picking, cold rolling, deceasing, annealing, leveling, finishing, polishing, etc, It not only achieves to the highest production efficiency and the most perfect automation control in the steel field by the production department, but also representing the outstanding and greatest level of steel rolling technology.

Our cold-rolled steel coils must be under further processes after annealing, including cutting head & tail, trimming, straightening, leveling, recoiling or slitting.etc

Delivery condition (strip,coil,sheet) | Grade based on DIN Standard | High quality heat treating steel strip, coil, sheet supply capacity and condition | |||

| Delivery condition (strip,coil,sheet) | Grade based on DIN Standard | Hardness<20HRC | Hardness 29-55HRC | ||

| Delivery condition (strip,coil,sheet) | Grade based on DIN Standard | annealed | hardened and tempered | ||

| Delivery condition (strip,coil,sheet) | Grade based on DIN Standard | thickness | Width | thickness | Width |

High carbon steel | CK50,CK55, CK60,CK67, CK70,CK75,C75Cr1, SK5 SAE1050, SAE1060, SAE1065, SAE1070 SAE1075 | 0.15-5.0mm | 8-600mm | 0.20-5.0mm | 8-600mm |

Alloy spring steel | 50CrV4, 51CrV4, 60Si2Mn | 0.20-5.0mm | 8-600mm | 0.20-5.0mm | 8-600mm |

Stainless spring steel | 3Cr13-6Cr13 | 0.20-5.0mm | 8-600mm | 0.20-5.0mm | 8-600mm |

Edge process | slit edge; both rounded; one side round, one side slit; square etc | ||||

Finish surface | polished (blue, yellow, white, grey-blue, black, bright) or Nature etc | ||||

Tolerance | thickness +/-0.03mm max; width +/-0.3mm max | ||||

Physical Property | tensile strength – 450-1850N/mm2 | ||||