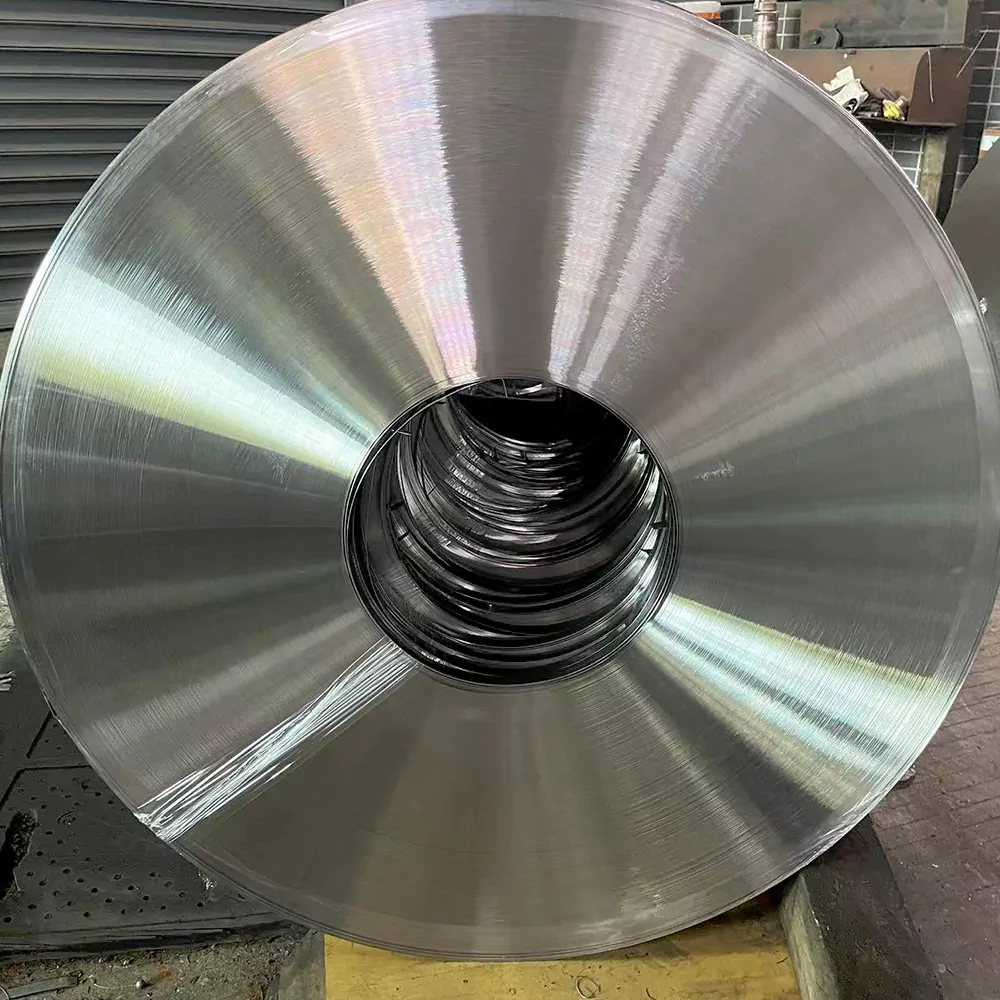

hot sales regular size(mm) for band saw blade steel strip | |||

0.5X15 | 0.56×16 | 0.6×15 | 0.6×20 |

0.7×20 | 0.6×25 | 0.7×25 | 0.7×30 |

0.7×35 | 0.8×30 | 0.8×40 | 0.9×50 |

1.0×50 | 1.1×60 | 1.0×90 | 1.0×100 |

1.1×100 | 1.1×120 | 1.1×130 | 1.2×120 |

1.25×150 | 1.3×150 | 1.47×150 | 1.47×155 |

1.2×180 | 1.25×180 | 1.5×180 | 1.75×180 |

1.47×180 | 1.47×230 | 1.65×230 | 1.65×260 |

Hardening and Tempering is a thermal process that strengthens steel strips through a controlled heating and cooling process. The hardening process involves heating the steel strip to above the critical transformation temperature for the given grade and then

rapidly cooling. The steel strip in this condition is extremely brittle and requires further treatment in the tempering. Then strips are reheated to a lower temperature and holding it at the given temperature for a given period of time. This process is done in an inert atmosphere to avoid oxidation. This type of steel strip has high degree of toughness and has flexible properties.

The Band Saw Blades steel strip thats made of superior material with excellent technology. Our heat treatment technology ensures excellent flatness, stable straightness, homogenous surface, and reduces machining time remarkably. In order to meet sophisticated and diversified customer needs, we provide our customers a variety of sizes with prompt deliver